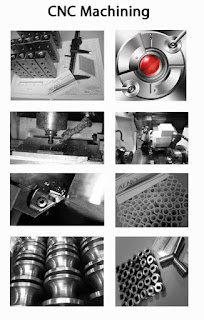

CNC Machining Central Coast

CNC Machining Central Coast | Solidworks | Turning | Milling | Grinding | EDM

Friday, November 6, 2020

Plastic Injection Tooling: Product Design and Tooling

Plastic Injection Tooling: Product Design and Tooling: ALNO the first choice when it comes to Product Design and Tooling. ALNO is a one-stop metal and plastic manufacturer. Our advanced full ...

Tuesday, July 5, 2016

Central Coast Professional Toolmakers - ALNO Product Services

Central Coast Professional Toolmakers

Mechanical Design Consultants

Mechanical Design Consultants

ALNO Product Services

Furthermore, thanks to the integrated parametric models, we can produce the work most speedily while maintaining the highest quality.

In terms of scope of works that team at ALNO Product Services undertake, we specialise providing a comprehensive machining service for both types of machining General Engineering and Toolmaking.

Complementing the machining services on offer is a full design suite from three dimensional modelling through to finite element analysis and finishing with detailed drafting.

ALNO Product Services offer services in both of the most popular mechanical design systems available today, Autodesk - Inventor with over 500000 seats sold and Dassault Systèmes - Solidworks with over 1000000 seats sold worldwide at the time of writing this document.

Staff and management at ALNO Product Services have committed a Customer Service - Charter which is based on providing the following principles:

- Deliver our promise

- Creative Solutions

- 1st Class Quality

Size of machining projects we undertake in general terms we prefer to limit our machining capabilities to components that a human can lift in and quantities in both small and large volumes.

Size of Design projects are only limited to our clients imagination.

If you are seeking Professional machining services with the optional design service please click on our price policy.

Finally if you have a tight deadline for delivery of your project it is best not to delay in contacting as generally our regular clientele keep us constantly scheduling work.

EDM | Precision Machining | CNC Machining | Food Grade Machining

Central Coast, Australia

New South Wales, Australia

Wednesday, March 16, 2016

CNC Precision Machinists

ALNO CNC - Machining was started more than 25+ years ago by Alan Nottingham offering CNC machining services as CNC Precision Machinists.

Over time, the team at ALNO CNC Machining have taken the company to new levels in terms of machining capabilities and Machining of different materials or the latest in new materials.

The team at ALNO CNC Machining offers expertise and accuracy in machining along with customer service, on-time deliveries, technical expertise and safety to our employees.

CNC Precision Machinists

In a business where precision is everything, having a clear focus is vital. For the last 25+ years, CNC Precision Machinists are focused on quality outcomes.

If you click through our site, our commitment to attain perfection in all areas is clear. From tolerances achieved, awards won and our facility list, it is obvious that we take accuracy & deadlines serious no matter how complex the job. Much of our expertise is in, but not limited to working with both ferrous and nonferrous metals including Stainless Steels, Titanium, Coppers tool Steels and super alloys.

We are in business for the long haul and want every partnership with our clients to reflect that. That means constant investing in new machinery, learning new management and shop-floor techniques, upgrading certifications and consistently updating our website to keep our partners customers fully informed of changes & our increasing capabilities.

We look forward to speaking with you about your precision CNC machining needs. If precision, experience, quality and friendliness are of the utmost importance, then ALNO CNC Machining, would enjoy partnering with you.

As CNC Precision Machinists ALNO CNC Machining offer custom precision CNC machining services, prototyping and high volume production services.

Our precision CNC Milling machines are equally versatile; we have up to 24000 rpm spindle speed capabilities. Our computer-programming center makes rapid communications possible to each CNC machine.

For more information on CNC Precision Machinists at ALNO CNC Machining contact

www.cnc-machining.com.au

Machining | General Engineering | Food Grade Machining | Toolmaking

CNC Machinery | Precision Machinery

www.cnc-machining.com.au

Machining | General Engineering | Food Grade Machining | Toolmaking

CNC Machinery | Precision Machinery

Labels:

cnc machining,

CNC Precision Machinists

Central Coast, Australia

Australia

Tuesday, September 29, 2015

CNC Machining | Sydney

CNC as a Management Control

Before go through into greater

detail of some areas that the CNC Machine imposes an influence, it is

interesting to know that a CNC Machine is not a machine control, yet it can be

used in management control. CNC is primarily an automatic machine. However, its

capacity to enhance the production process also greatly increases the potential

control that management has over the manufacture process. Management is

concerned with planning, organizing and efficient usage of all factors and

resources that are available.

CNC and Design

When a component has to be

manufactured, it first has to be designed. The adoption of CNC will immediately

impose a certain influence on the design process. Detailed working drawings

will be produced in accordance with accepted CNC conventions. The design

process also will be influenced by the application of computers which is used

to convert all designs created into data. Once the design is converted the data

can be transmitted directly to the memory of the CNC machine tool ready for manufacturing.

CNC and Quality Control

Since the process is now

automatic, better quality in terms of dimensional and geometrical accuracy is

reached. Because of the uniformity of the products, the processes of fitting

and assembly can possibly be streamlined. The decision to invest in CNC machine

tool must not be taken on the basis of technology alone. It is important

understand that if the management fails to acknowledge these additional

benefits then the CNC installation will be less effective. The level of the

benefits is dependent of the user. It is minimal when the CNC is used as a

machine control and reach the maximum when the CNC is adopted as a management

control.

Labels:

cnc machining,

CNC Quality Control,

CNC Turning,

Toolmaking

Friday, September 4, 2015

ALNO Guidelines to Injection moulding (Part 2)

Wall thickness

The wall thickness of injection-moulded parts needs to be observed

properly to avoid potential problems such as leaving sink marks and letting

your part warp. At ALNO we recommend

different thicknesses depending on the material you are using and the eventual use

of your final product.

Surface finish

The finishes available to you at ALNO product services vary according to

you intended use and can range from all ranges of cosmetic finishes, EDM or

higher-end finishes.

Radii

ALNO uses an automated CNC milling process to create the mould for your

parts. However, some part edges will end

up with a radius rather than a sharp corner or edge. This does not typically involve

the need to change a model, but the designer should be aware of these before

moulds are made.

ALNO product services manufactures all your parts locally in our workshop

on the New South Wales Central Coast. We

provide innovative solutions and high-speed solutions so contact us today for a

quote.

ALNO Product Services

CNC Machining | Injection Moulding

Monday, August 31, 2015

CNC Machining - 1st Class Quality

The team at ALNO Product Services offer CNC Machining with 1st Class Quality

CNC machines are pivotal for mass-producing exact components

or products within a limited space of time.

Computerised machines that utilise numeric control to send

precise commands to machinery that, in turn, crafts identical products

constantly.

CNC machines are quickly becoming the step forward for a

wide range of manufacturers looking to create high-quality products in a short

space of time.

At ALNO Product Services, we combine top-of-the-range CNC

machines with our helpful, qualified experts to deliver a service which

promises the best results in the shortest time possible.

Offering CNC machining to clients in Sydney and the Central

Coast, our team are able to deliver quality products for a wide range of firms

operating across our state.

Whether industrial or commercial, we can deliver a

significant amount of products within a short space of time.

Due to the nature of CNC machines, these products aren't

under the risk of human error as other mass-manufactured products would be:

Instead, the machines, thanks to precise calculations, can create a vast range

of products and components in a range of materials within a short space of

time, and without the risk of human error creating a faulty product or batch

that could ultimately prove costly.

As the machines are highly accurate, it also means that less

material is wasted during the crafting time, which means great savings for our

customers.

With 20+ years experience of CNC machining, delivering

consistent products quickly, we are the firm to turn to when you need products

in a short lead time frame.

Whether you're looking for a large batch to deliver, or a

one-off prototype as a test, we will gladly acquiesce to any request given to

us, and are always happy to help our clients from the design process through to

the creation of their product.

CNC Machining

Precision Machining

If you are in need of a quick product, component or

prototype, then don't hesitate to enquire to our friendly, experienced staff by

contacting us

Central Coast, Australia

Sydney NSW, Australia

Sunday, August 9, 2015

ALNO Guidelines to Injection moulding (Part 1)

Injection molding

Injection molding, a very simple way to mass produce plastic parts but can also be a very tedious and time-consuming task. When you want a new plastic part through injection molding, ALNO product services provides a comprehensive injection molding solution. Before we make your mold however there are a few guidelines we ask you follow to ensure a high quality mold that can last you the entire life that you want to sell your plastic injection molded product.

Mold Size

Please communicate how large you want your part to be early into the manufacturing process. Our machines provide a large range of solutions but there are some limitations to the size of the mold that we can produce. Depth of the part, degrees for draft (angle) are also important considerations. You must also take note that deeper parts may be limited to a smaller outline.

Drafting the mold

The draft is a taper that needs to be applied to the faces of the part to stop it from being parallel to the motion of the opening of the mold. This keeps the part from being damaged due to scraping as the part is ejected out of the mold. Some draft recommendations are as follows:

- 0.5 degrees on all vertical faces is strongly recommended

- 2 degrees works well as a standard solution and in most circumstances

- 3 degrees is an industry minimum for when metal slides on metal

- 3 degrees is the recommended requirement for a light texture

- 5 or more degrees is the recommended requirement for a heavy texture

Tolerances for your injection molding part

For all of your injection molding needs at ALNO Product Services we can maintain high machining tolerances with an included resin tolerance, contact us or visit our website for more details.

Labels:

ALNO Product Services,

Injection Moulding,

Mechanical Design,

Plastic Injection Moulding,

Product Design,

Production Development,

Production Machinery

Central Coast, Australia

Melbourne VIC, Australia

Subscribe to:

Comments (Atom)